Cupolex

What is Cupolex?

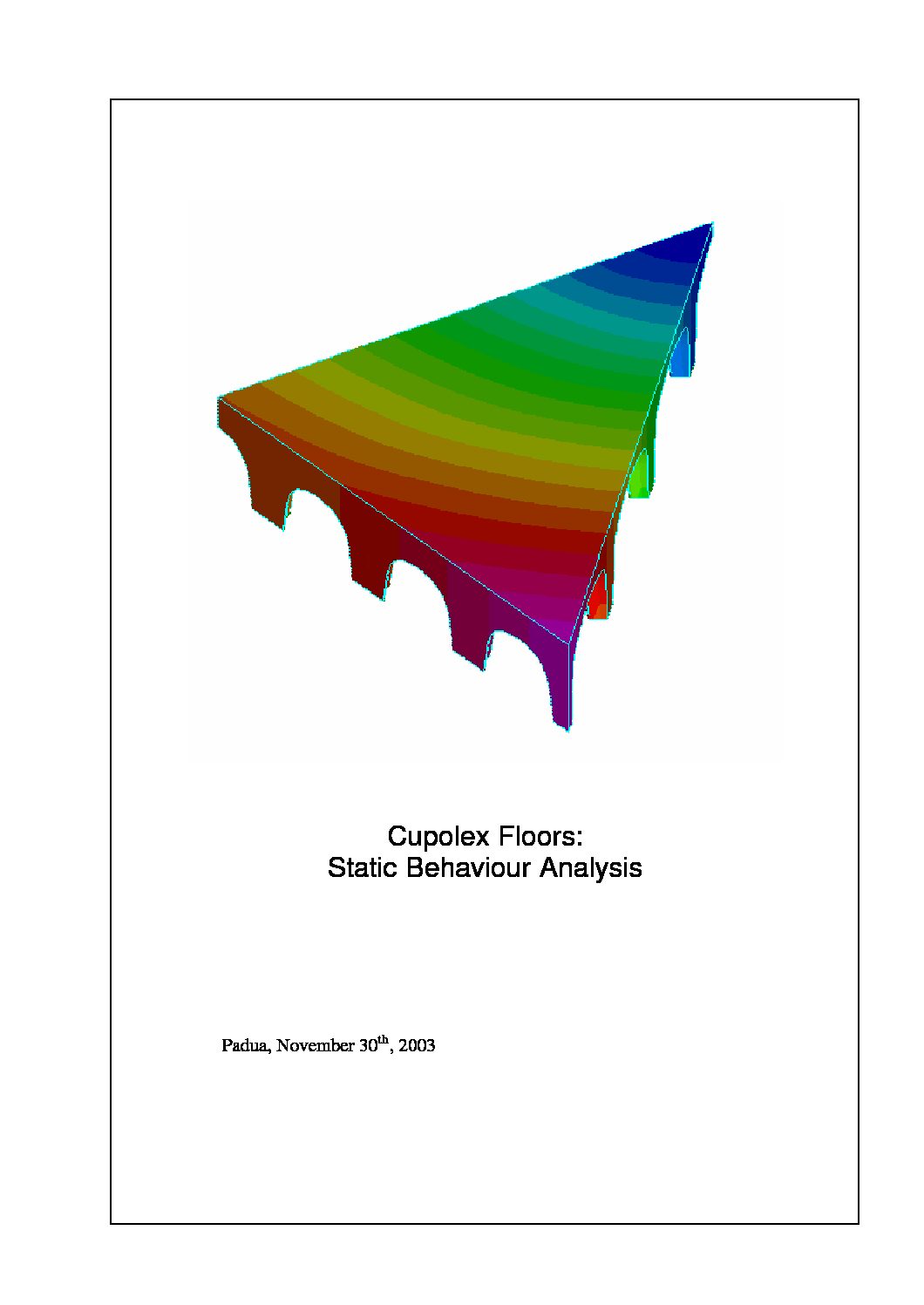

Cupolex is a sacrificial void forming system which utilises 100% recycled and recyclable non toxic interlocking dome structures to create concrete foundations. Concrete is poured over the molecular dome forms to create a floating or structural concrete slab.

How Cupolex works?

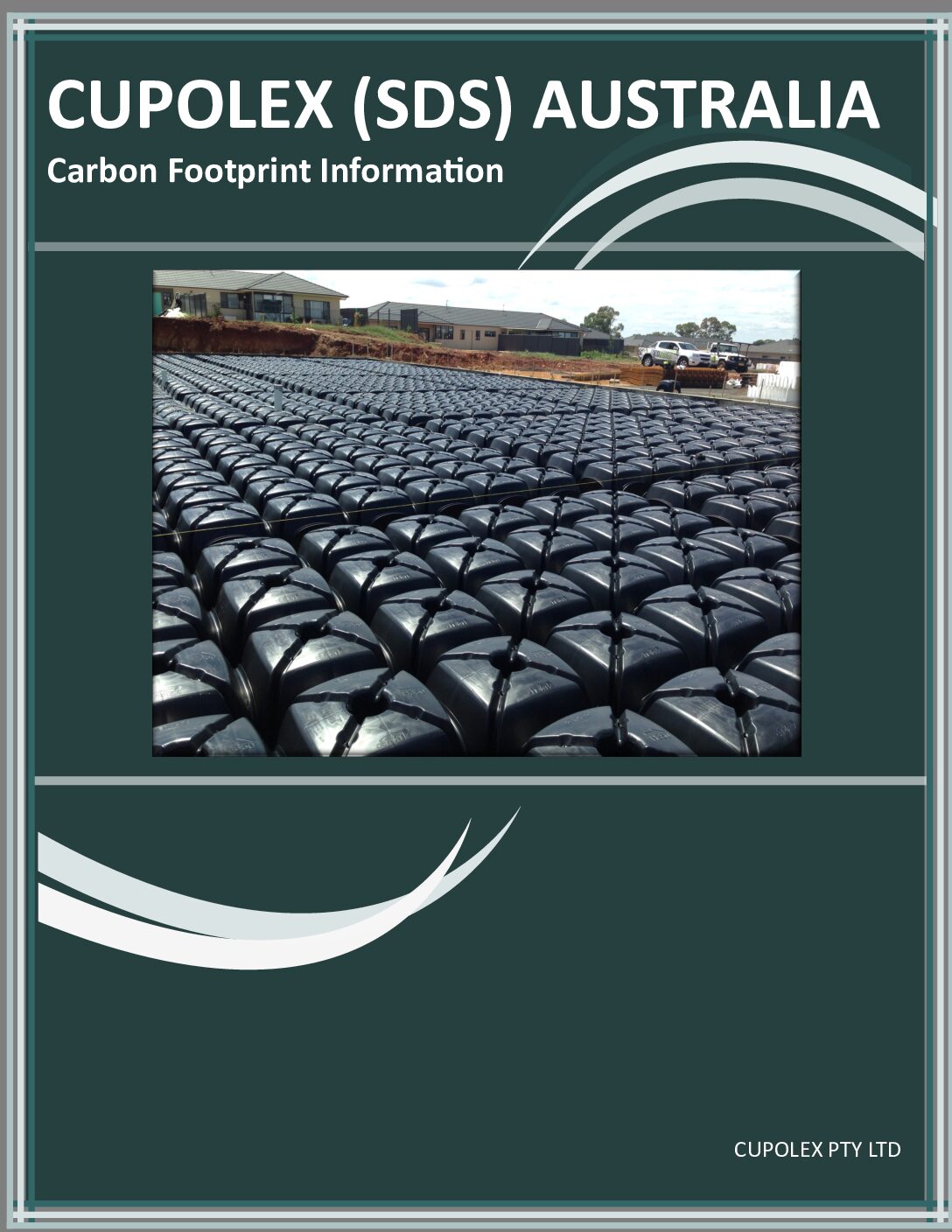

Cupolex is made from 100% recyclable nontoxic materials. At Enviro Slab our goal is to incorporate more sustainable practices and products into the building and construction industry. Cupolex has been introduced to help reduce our carbon footprint for concrete slab foundation systems for new buildings. Several tests completed using Cupolex system demonstrates how it performs in terms of sustainability and environmental benefits. The results have indicated that Cupolex can improve thermal efficiency in homes, and in turn could increase a home’s energy rating. Cupolex also reduces site traffic and transportation costs when compared with alternative concrete slab foundation systems therefore reducing CO2 emissions. There are also significant environmental benefits. Unlike polystyrene there is no risk of residue ending up in waterways. The air cavity underneath the Cupolex domes resists mould and mildew for a healthier work environment. Cupolex could also reduce the amount of concrete and steel mesh required for the concrete slab making it a great solution for reducing materials and cost for the builder.

Why Choose Cupolex?

The benefits

Light weight & Durable – Cupolex is light weight and durable withstanding elements withstanding weather elements without aging, breaking or tearing.

Cost Effective – The fact that Cupolex is fast to install saves on labour costs as there is no cutting required (except for pipe penetrations)

100% recycled materials – Unlike the polystyrene alternative, Cupolex is made from 100% recycled polypropylene Choosing products like Cupolex reduces the use of non-renewable resources which eventually ends up in landfill. Cupolex can also reduce the amount of concrete and steel used in a project therefore reducing material shortages, which are common in today’s building boom.

Made in Australia – Cupolex domes are made in Australia to support more jobs and manufacturing in Australia.

Time saving benefits – Around 150-200m2 of Cupolex can be installed by 2 people which could save you time when compared to other foundation systems. The interlocking nature of the Cupolex system also eliminates the need to cut the domes to size saving you time.

Versatile – Cupolex is incredibly versative and able to used on a range of project types both small and large, from small sheds to residential homes and large commercial buildings such as shopping centre’s and high rise buildings.

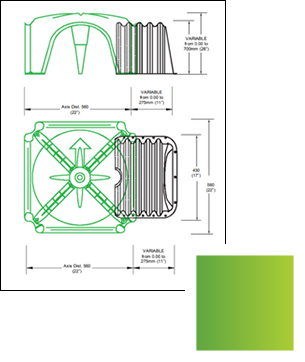

Specifications

The Cupolex system contains three main components and come in 3 different sizes depending on your site classification.

Dome Types Explained

H200 Dome

This dome is only used in conjunction with the H260 for wet area and alfresco set downs. When coupled with the H260 it will allow for a 60mm set down, whilst maintaining the minimum slab thickness of 60mm.

H260 Dome

This dome is utilised for slabs designed on sites with the classification of A, S, M and some H1 sites. This dome is also utilised for set down areas when coupled with the H350.

H350 Dome

This dome is utilised for slabs designed on sites with the classification of H1, H2.

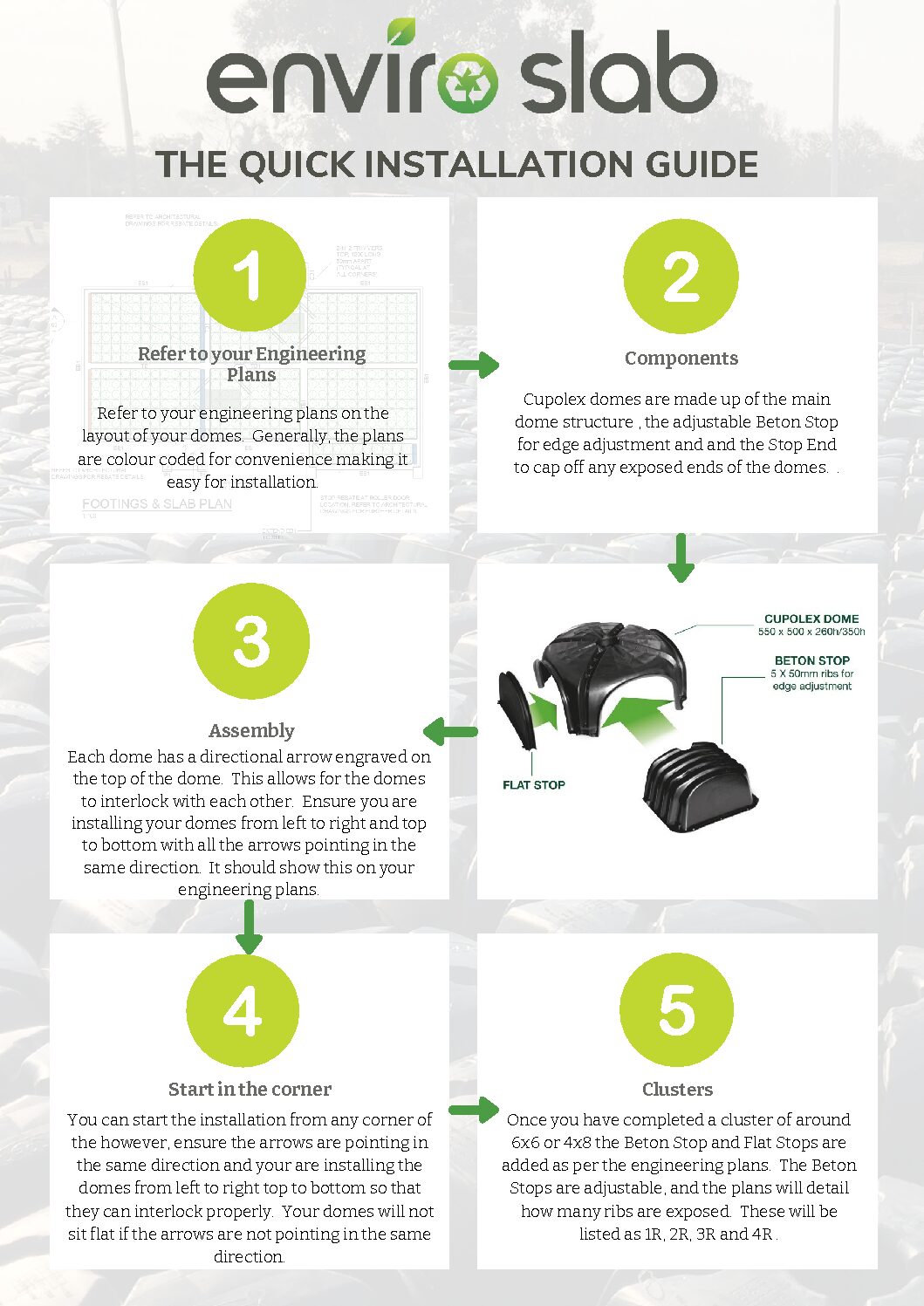

Beton Stop

The Beton Stop is designed to enclose the side openings of the dome structure. Beton Stops also accommodate for the dimensional variations in concrete slabs with adjustable ribs. As a result, they do not require cutting, this allows them to be suitable for any concrete slab dimensions.

Flat Stop

This is designed with no adjustment to close off the side opening of the cupolex domes.

Application of Cupolex

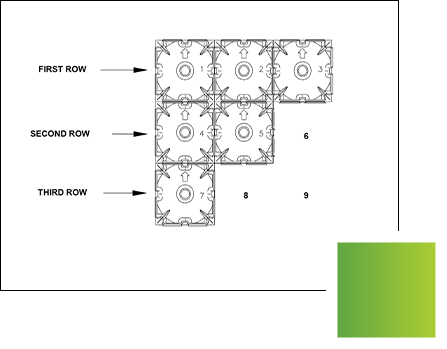

Like any weight bearing structure Cupolex must be designed by qualified structural engineers. We can arrange engineering and re-engineering using the Cupolex system if you require it. Preparation for the concrete slab is done the same as any other standard slab type. The domes are installed from left to right, top to bottom with all the arrows on top of the domes pointing in the same direction as per the engineering plans.

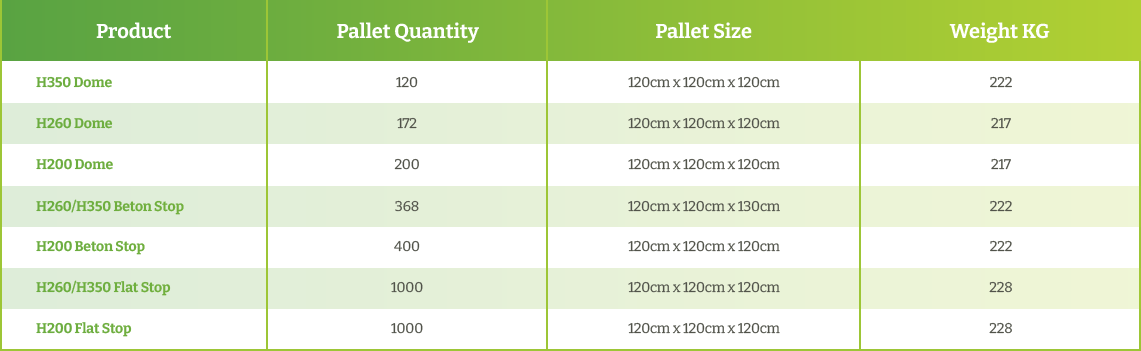

Cupolex Pallet Quantity, Pallet Dimension, Weight

Download Product

Information Pack