What is the difference between using steel mesh reinforcement to Glass fibre reinforcement?

What is glass fibre reinforcement?

Glass Fibre reinforcement is making waves in the building and concreting industry. For many years the material of choice for concrete slabs has been steel mesh. More recently, the introduction of glass fibre reinforced polymer (GFRP) rebars has provided an alternative to steel reinforcement.

Steel reinforcement

The steel industry is one of the biggest producers of carbon on the world. It is estimated that around half of all steel produced goes to the construction industry and 44% of construction’s steel consumption is used for reinforcement. This equates to a whopping 1.5% of global carbon emissions attributable to steel rebar alone. (Madewell Products, 2021). One of the biggest components of using steel reinforcement is corrosion, which in severe cases can lead to structural failure of the concrete slab. Steel also is heavy, has increased in cost over recent months as a result of the building boom and is heavy to carry and transport.

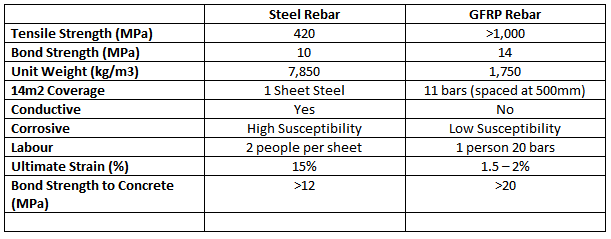

Comparison Graphic

What is the difference between GFRP and steel rebar?

The introduction of glass fibre reinforced polymer (GFRP) has provided some additional benefits not previously supported when using the more traditional steel rebar. One of the major differences between Steel rebar and the alternative GFRP is the added strength that GFRP offers. GFRP can have more than double the tensile strength of steel reinforcement.

GFRP Structural Benefits

The structural differences in both GFRP and steel means that their structural performance differs significantly. One of the largest disadvantages of using steel rebar is its corrosive nature, creating weakness in the steel. More concrete could be required when compared to GFRP rebar and adds additional cost to the lifespan of the slab due to maintenance and repairs if corrosion occurs. GFRP is also significantly lighter and easier to manoeuvre and transport than steel rebar. The low susceptibility of GFRP paired with the increased tensile strength makes it an ideal choice as a structural rebar preference and structural performance over the lifespan of the concrete slab.

Conductivity of GFRP vs steel rebar

Stray currents have been known to occur when steel rebar has been used in conductive environments such as rail corridors. Typically, stray currents can lead to safety hazards and can result in accelerated corrosion of fixtures, fittings and building components due to anodic reactions between dissimilar metals.

Enviro Slab is currently offering Durabar a GFRP rebar suitable for flatwork or slab on grad applications such as driveways, paths, shed slabs and tennis courts. If you would like to learn more about GFRP and how it could be a good alternative to steel rebar for your concrete slabs contact us or register for an information pack.